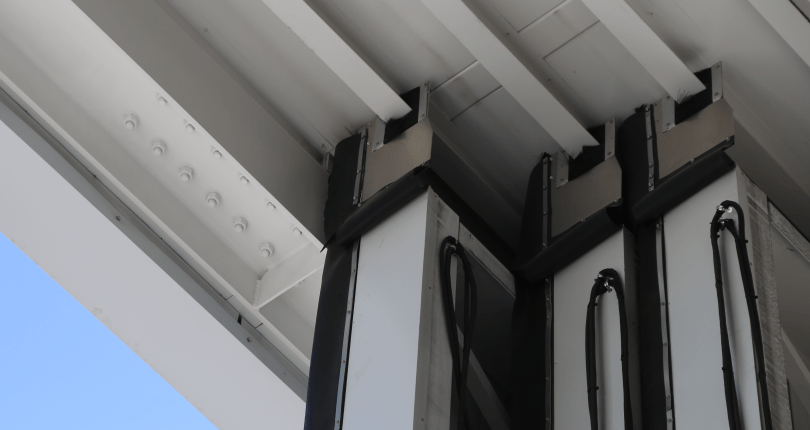

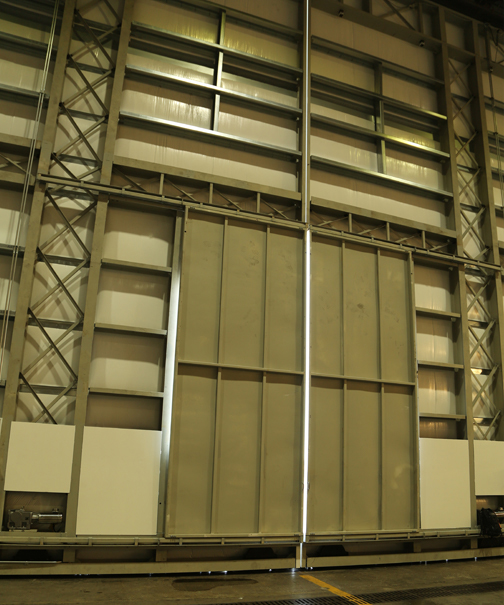

Bottom Rolling Door Structure

All materials used for the construction of rolling door system components are new and free from defects or imperfections.

Hot rolled structural steel shapes conform to ASTM A36 with a minimum yield strength of 36,000 psi. Tensile strength is 58,000 to 80,000 psi.

Cold formed structural steel shapes, such as cee’s, zee’s and channels, conform to ASTM A570 Grade 55 with a minimum yield strength of 57,000 psi.

Welded mechanical tubing conforms to ASTM A-500 Grade B with a minimum yield strength of 46,000 psi. Typical tensile strength is 58,000 psi.

Mechanical fasteners critical to the assembly or function of a rolling door system are either ASTMA-325 or SAE Grade 5. Bottom track support anchor bolts or threaded rod may be ASTMA-307 or equivalent.

Elastomeric sealing elements that seal the sides and bottoms of the door systems are fabricated using EPDM type 40 elastomer. EPDM is for outdoor and high temperature applications. It resists ozone, steam, water, oxygenated solvents as well as animal and vegetable oils.