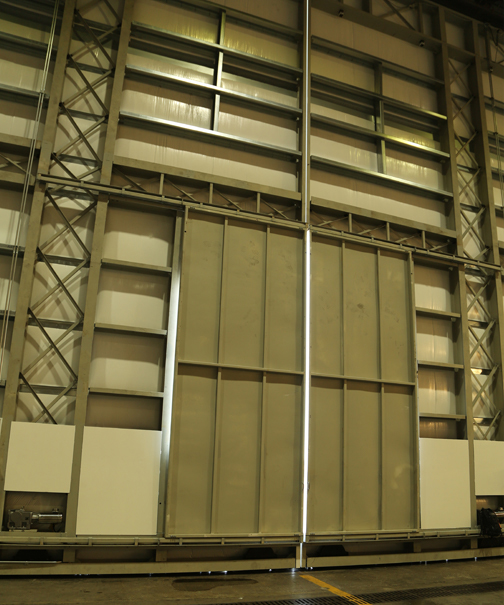

Hydra-Eze Hydraulic Door Lift System

All Hydra-Eze® Hydraulic Door systems are equipped with two industrial double-acting hydraulic cylinders rated at a minimum of 3000 PSI capacity to ensure safety, aid in preventing system failure, and to provide a long service life. The hydraulic cylinders are rebuildable for minimal maintenance costs.

Hydraulic operators are provided to open and close the door, and they come filled, purged and ready for bolt-in installation. The operator can hold the door in any position of travel, and it conforms to national electric codes. All operator systems use a keyed lock out to prevent unauthorized personnel operating the system.

Operators are heavy duty 2HP to 5HP (or larger) TEFC -type and mounted to the center above the door for balancing. Standard voltage is 230V single phase with 115V single phase. Three phase voltages (208V, 230V, 460V) are optional. Attached hydraulic pumps operate at a minimum 1000 PSI to a minimum of 2000 PSI as required for the system. This also acts as a margin of safety ensuring the pumps will not exceed rated operating pressures of all other hydraulic components.