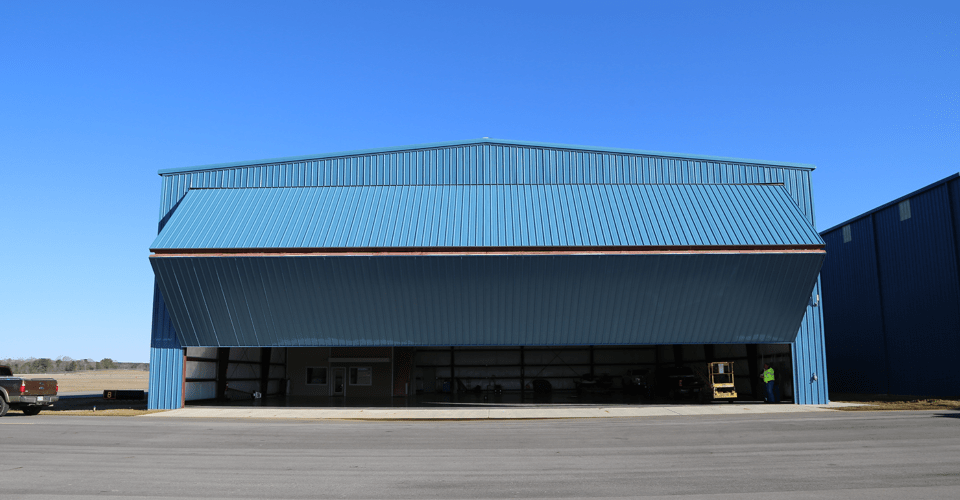

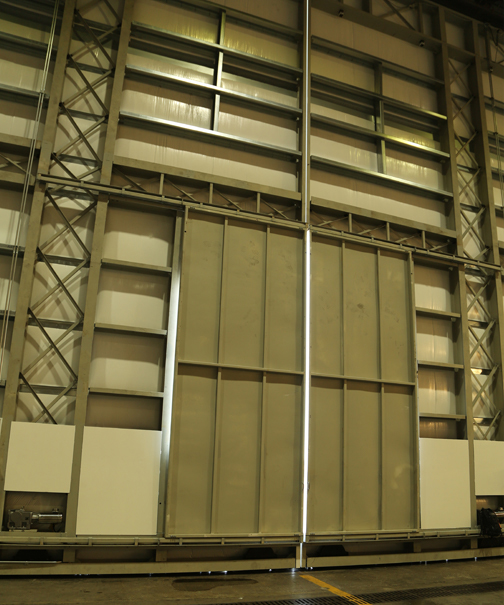

The Bi Fold Door Structure

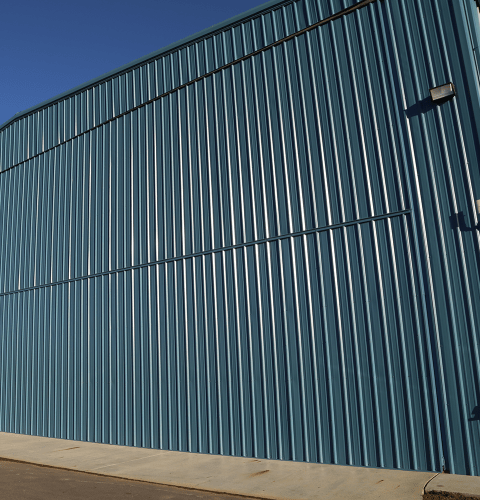

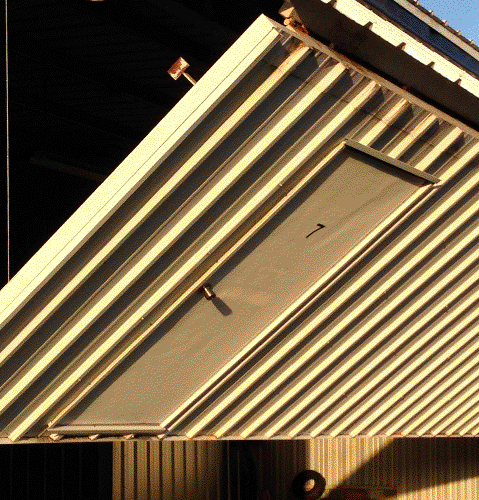

Bi-Fold door frame shall be fabricated with ASTM A500 Grade B welded steel tubing not less than 11 Gauge wall thickness with minimum yield strength of 46,000 psi. Except for the bottom corners where the guide rollers are installed, all exterior corners are mitered at 45 degrees and welded on four sides for strength and to prevent water or moisture from entering the frame. Miscellaneous structural members shall conform to ASTM A500 and ASTM A-36 with minimum yield strength of 36,000 psi. Exterior to be left flush for customer provided exterior sheeting.

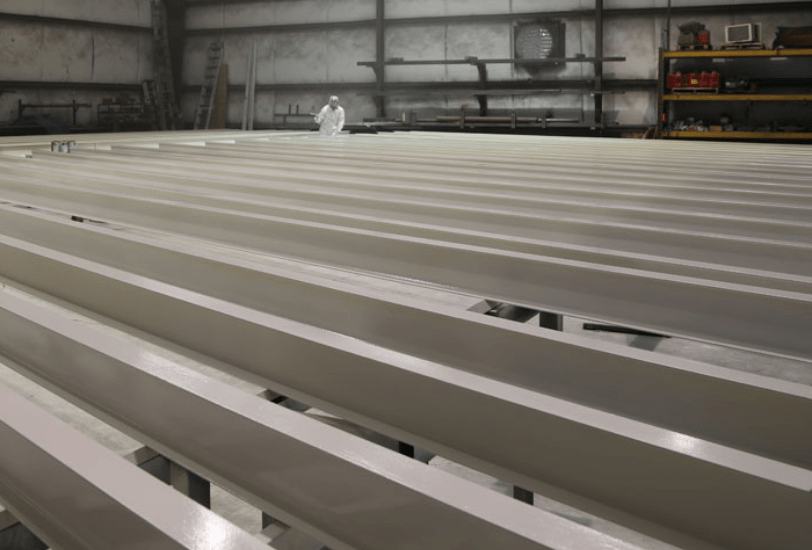

Framing members shall be square and true to dimension in all directions and shall not be out of line horizontally or vertically more than 1/8 inch in 20 feet. Door sections shall be fabricated in a manner so as to prevent bowing, racking, or warping during fabrication in order to hold the sections to specified tolerances. Welds which could affect the fit or function of the door shall be ground smooth.

When required, integral trusses shall be mounted to the interior of the horizontal framing members.