Hercul-Eze® XP 500 Series

Door Operator

Door Operator

The Hercul-Eze® “500” by WELL BILT INDUSTRIES patented rolling door operator provides a compact and efficient means of opening and closing rolling door systems up to 60,000 lbs. Hercul-Eze® “500” by WELL BILT INDUSTRIES operators utilize two industrial solid fill tires in contact with the hangar floor material to provide the tractive force to move the door system. Hercul-Eze® “500” by WELL BILT INDUSTRIES operators are available in two types; the “In-The-Door” model and the “Out-Of-Door” model. The “In-The-Door” model installs in a rolling door leaf with 10″ or greater frame width and allows the door leaves to stack in a pocket or outside the building without special allowances for clearance. The “Out-Of-Door” model typically installs on the inside surface of a system in which the basic frame width is less than 10″ or the door structure is such that an “In-The-Door” model can not be installed.

|

Depth |

Width |

Height |

Weight |

|---|---|---|---|

|

9 ½” |

X 53 1/2″ |

X 40″ |

315 lbs |

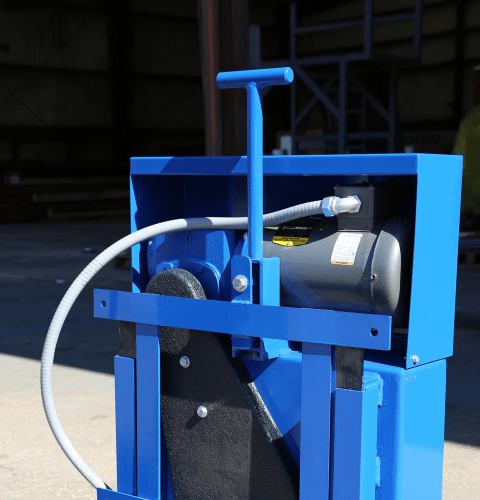

The basic drive housings of the Hercul-Eze® “500” by WELL BILT INDUSTRIES door operators are fabricated from low carbon steel plates welded or bolted to fabricate the basic housing assembly. The two traction wheel axle shafts are supported by two serviceable ball bearing flange bearing units each. The driving tire is an industrial solid fill tire designed to operate at typical loading conditions.

Drive shall be provided by an electric motor directly coupled to a right angle worm drive gear reducer. The gear reducer, in turn, drives the traction wheel axle shafts through a heavy duty roller chain system consisting of # 50 chain and hardened sprockets.

Electric motors used in Hercul-Eze® “500” by WELL BILT INDUSTRIES operators shall be 5 horsepower minimum TEFC three phase power. With the high ratio worm gear speed reducer, no electric brake is necessary to stop door movement. Primary electrical is per customer specifications while control voltage remains 24 VAC.

The standard Hercul-Eze® “500” by WELL BILT INDUSTRIES operator power is supplied through a drape wire system where the cable is draped from leaf to leaf. Wire size and number of conductors in the cable are adjusted to meet system requirements.

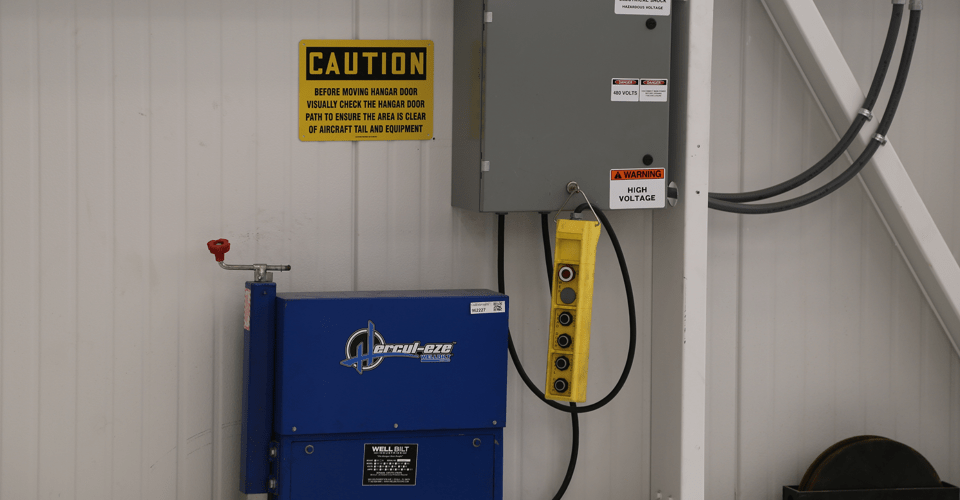

All hard wiring for power supply; over current protection, disconnecting means and hard wiring within the door shall be the responsibility of the installer or the electrical contractor.

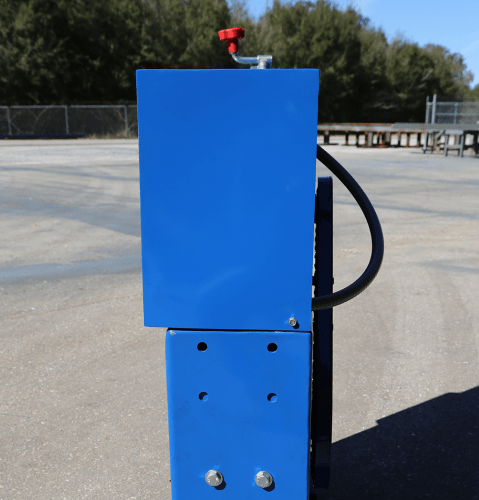

Tractive force is controlled by two opposing crank operated adjusting screws whereby the downward pressure on the solid fill tires can be increased for more traction or can be backed off so that the tires can be completely disengaged from the driving surface so that the door leaf can be moved manually. This feature qualifies under National Fire Protection Association # 409 for aircraft hangars.

The basic Hercul-Eze® “500” by WELL BILT INDUSTRIES operator is a manual unit. The operator is furnished with a controller which is pre-wired and connected to the motor with an approximately six foot length of coil cord and “walk with” pendant; open/close control buttons.

Automatic open with automatic close system allows the door system to be opened or closed with a flip of the switch. The hangar door travel can also be stopped at any point of its travel by selecting the “Stop” setting. In these installations, the controller is normally wall mounted near one end of the door system. Door travel at open and closed positions is controlled by micro-switches mounted on the building above the door leaves.

A remote control option is available with the automatic control system. With the remote control option the door system can be activated to open or close from up to 1,500 feet from the receiver unit.